Diamond market trends: Transition from natural to Lab Grown Diamonds

Lab grown diamonds are more available in today’s jewelry market than ever before due to advancement in their Chemical Vapor Deposition (CVD) growth process. CVD is a newer and much easier method compared to the traditional synthetic diamond growing method, called High Pressure, High Temperature (HPHT) method. HPHT involves apparatus that imitates natural diamond forming conditions that occur in earth’s mantle. Typically, in CVD method, carbon carrier gas is decomposed in a vacuum chamber that crystallizes on a diamond seed, and we get lab grown diamond in couple of weeks in contrast to the natural case which normally takes billion years.

From Flaws to Flawless

Among the various types of CVD process, the MPCVD method is quite popular due to low temperature and pressure condition. Recently, India, specifically Surat has become hub of the Lab Grown Diamond market adopting MPCVD technique to grow LGD. For flawless diamond growth using MPCVD, the key process parameter must be maintained with extremely tight control. In fact, MPCVD diamond often shows low color grade, sometimes brown color at their as grown state due to presence of Nitrogen (N2) element. Recognizing incorporated impurities like N2 or Si may deteriorate the diamond color grade and properties. Hence, it is important to monitor the plasma during the growth process so that any source of nitrogen or other impurities, in the feed gas or from a leakage in the chamber could be eliminated.

HORIBA OES tool for Plasma monitoring in LGD

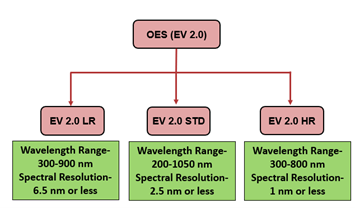

HORIBA has developed a wide range of optical sensors, based on optical emission spectroscopy (OES). These sensors are used for plasma diagnosis, process optimization. Besides the hardware, some of the sensors are driven by a state-of-the-art software platform including advanced algorithms for leak detection, endpoint detection and process monitoring. For the Lab Diamond Application, HORIBA offers three versions of OES with Process monitoring application software. These sensors are categorized based on the wavelength range they cover, and spectral resolution as shown in Figure 1.

Gaining clarity: OES adaptation to MPCVD chamber

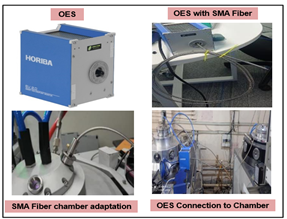

HORIBA EV 2.0 HR, the simplest tool that comes in two configurations: basic API and with upgraded PC configuration. The basic system includes the spectrometer, a SMA fiber cable that delivers the collected signal from optical window of the chamber to the interface of the spectrometer, and a monitoring software. The spectrograph shows variation of the intensity of the radical emission against wavelength.

HORIBA API-OES tool is experienced in tracking commonly used gases in diamond growth such as CH4, Ar, H2 O2 and N2 and their corresponding different plasma radicals and provide the corresponding emission wavelength spectrograph. HORIBA OES has proven track record in handling the complexity of LGD growth process during insitu analysis of impurities such as Si from quartz windows, and/or CN from N2 leak in plasma chamber.

Real time monitoring diamond growth process with HORIBA OES

Typically, 6-12KW microwave assisted PECVD reactor has been used to grow diamond where CH4 used as a source of carbon and H2 as a ignition source for plasma. Different gases (as a radical form in plasma) can also be a part of the process to accelerate and control the color of diamond. However, C2 radical plays a crucial role for diamond growth rate.

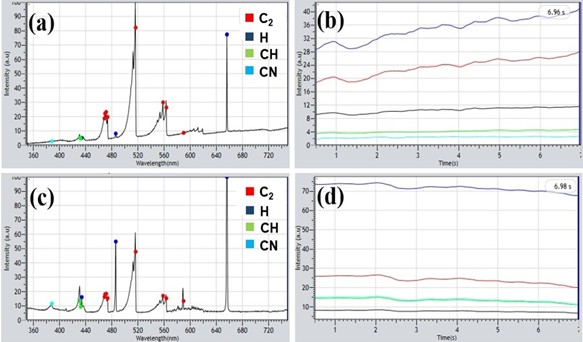

Plasma diagnosis using OES method proves to be powerful technique to identify constituent radicals driving the growth. For example, figure 3 shows emission spectra obtained during the growth from two different diamond growing chambers using HORIBA EV 2.0 HR system. Along with C2 and H2 radicals emission of CN radicals observed in plasma of chamber 2. Spectrum from chamber 1 shows the emission from hydrogen (H) and carbon (C) radicals like Hβ at 457 nm, Hα at 657 nm, CH at 430 nm and C2 in the range of 450- 475 nm & 500-570 nm. Thus, OES is a powerful tool to identify all radicals present in plasma during growth. Seeing the CN emission peak without N2 gas presence confirms leak in the chamber and hence protects the users from wasting time and money. In Figure 3 (b) and (d) show the stability of intensity of C2, H, CH and CN radicals’ emission with respect to time from chamber 1 and 2 respectively. In-situ plasma diagnosis during CVD growth process is a unique way to get defect/ impurity free diamond having properties suitable for specific application.

Sum Up

HORIBA OES diagnostic data provides useful information related to impurity & leak in the chamber which is essential to model a cost-effective diamond growth process. Today, diamond is not only valued as gem but gaining technological interest due to its optical transparency coupled with other unique physical and chemical properties. In this regard, in-situ plasma diagnosis during CVD growth process is a very important task to get defect/ impurity free diamond having properties suitable for specific application. HORIBA OES (EV2.0 HR) is a reliable, in-situ but non-invasive monitoring method applicable in plasma CVD process and it has been widely accepted for leak detection and impurity analysis in Indian Lab Grown Diamond industry.

Leave a Comment

Comments